hardness test using vickers test|vickers hardness test theory : manufacture The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The article is all about the principle and application of Vickers hardness test. + 86 755 61301520;

[email protected]; Search.

webSomething went wrong. There's an issue and the page could not be loaded. Reload page. 170K Followers, 968 Following, 2,113 Posts - See Instagram photos and videos from Mc Kolos (@kolosoficial)

{plog:ftitle_list}

WEBNip BR é um provedor de internet banda larga e telefonia fixa que oferece planos acessíveis e serviços de qualidade. Conheça as vantagens de ser um cliente Nip BR e aproveite as promoções exclusivas.

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.How Does a Vickers Hardness Tester Work? 1. Preparation. 2. Application of Load. 3. Indentation. 4. Measurement. 5. Calculation. 6. Determination of Hardness. 7. Reporting. Advantages of Vickers Hardness Tester. 1. Broad .Vickers Hardness Testing Formulas, Calculator and Review. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid .

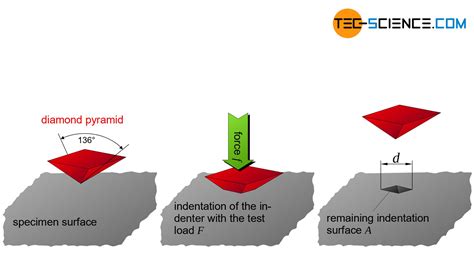

The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of .The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The article is all about the principle and application of Vickers hardness test. + 86 755 61301520; [email protected]; Search. For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the . Schematic representation of the Vickers test is shown in Figure 1. Further information regarding existing standards and procedures can be found in references [1,2]. Vickers hardness formula. The Vickers hardness (HV) is calculated using the following Vickers hardness formula:.

A method that can be used for figuring out a material’s hardness—a measurement of its resistance to deformation in the presence of force—is the Vickers hardness test. While it finds use in other materials like ceramics & some polymers, this test is widely employed in the metallurgical area. Vickers Hardness Testing Machine. . media in order to obtain a specific microstructure of steel. These heat-treated samples were then tested mechanically using the Brinell hardness test (BH .Hard anodised parts are tested for hardness using the Vickers test. On average, hard anodised aluminium 6082 can achieve values in the range of 300 to 500 HV, to put that into perspective, in its untreated state it has a hardness range of 80-95 HV. Exact hardness is entirely dependent on process parameters, such as anodising time, temperature . EN ISO 6507-1 and ASTM E92 are two widely recognized standards for Vickers hardness testing, both of which use a similar test method and offer multiple test force options. EN ISO 6507-1 specifies he following are the three ranges of test force and their corresponding Vickers hardness test designations: F ≥ 49.03 N - Designation: HV 5 .

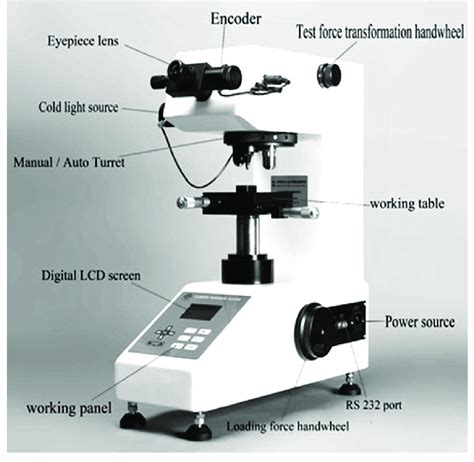

vickers hardness testing machine diagram

Vickers hardness test is a standard method for measuring materials' hardness, which is commonly used to measure the hardness or softness of substances like metals, minerals, and plastics. Here's the article for you to everything about Vickers hardness testing, including basics and principle, Vickers hardness test procedure, formula and calculation.

In this blog, we’ll delve into the Vickers Hardness Test and discuss when it’s best to use this method over other metallurgical hardness tests. Understanding Hardness Testing Hardness is the resistance of a material to deformation, and it is an essential property for evaluating a material’s ability to withstand mechanical stress and wear. .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .

Macrohardness Testing: While primarily a microhardness test, Vickers hardness testing can also be adapted for macrohardness testing of larger samples. General Purpose Testing: Vickers hardness testing is versatile and well-suited for general-purpose hardness testing across various industries and applications. When to Use Knoop Hardness TestingThe three primary methods of testing hardness in engineering are the Brinell hardness test, the Vickers hardness test, and the Rockwell hardness test. What is the test for hardness? The test of hardness is a procedure to determine the resistance of a material to deformation, scratching, or indentation. It's conducted using various methods like .The Vickers method has the following advantages: The Vickers method can be used with any and all materials and test specimens, from soft to hard, as the procedure covers the entire hardness range.The Vickers hardness test was developed by George E. Sandland and Robert L. Smith at Vickers Ltd. in the year 1921, as an alternative to the Brinell method to determine the hardness of materials. This Vickers hardness test is usually easier to use compared to other hardness tests. The reason is the required calculations are not dependent on the size of the indenter.

vickers hardness test theory

Why use the Vickers Hardness Test? The Vickers hardness test method is used for the following reasons. Universal Indentation – Due to the universal shape of the indenters of the Vickers hardness tester, it requires less calibration .

There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and Vickers hardness test. The Vickers hardness scale, named after the company where it was developed in 1921, is . The Basics of Vickers Hardness Testing. Vickers Hardness Testing is based on a straightforward principle: the depth or size of an indentation left by an indenter in a material is directly proportional to the material's .

mini r56 compression test

The Vickers hardness test is based on the principle of indentation hardness, where a diamond indenter with a square-based pyramid shape is pressed into the surface of the material under a specified load. The diagonals of the resulting indentation are measured using a microscope, and the Vickers hardness value is calculated using a formula that .What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a mineral is defined as its "resistance to being scratched". A list of the Mohs Hardness Scale Minerals is shown in the table below.

Most ZwickRoell Vickers hardness testing machines use a software program to automatically evaluate this indentation. Depending on the level of automation, Vickers hardness testing machines can also be used to test hardness curves. Our accessories portfolio includes different specimen grips, with which a wide variety of specimens, often .The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests .The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the test indentation is very small in a Vickers microhardness test, it is useful for a variety of applications such as: testing very thin materials like foils or measuring the surface .

Introduction to Vickers Hardness Test The Vickers hardness test, developed in 1921 by Robert L. Smith and George E. Sandland of Vickers Ltd., provides an alternative to the Brinell hardness test with a simpler scale. While it can be used to test the hardness of metals and other hard materials, its main focus is on [.]Brinell Hardness Test: Using a spherical indenter, this test determines the hardness by measuring the diameter of the indentation created by a known force. It’s suitable for materials with coarse grain structures or rough surfaces. . Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads .The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the test indentation is very small in a Vickers microhardness test, it is useful for a variety of applications such as: testing very thin materials like foils or measuring the surface .

vickers hardness test pdf

The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the indentation left in the .Vickers number 1 2 Average 1 0 0 0 312. 2 0 0 0 315. 3 0 0 0 317. 4 0 0 0 292. ANALYSIS Hardness Value: A measurement of the material's hardness is provided by the test's Vickers hardness number. Greater hardness is indicated by a higher HV. Vickers hardness values are a useful tool for comparing the hardness of various materials .

vickers hardness test explained

vickers hardness test diagram

vickers hardness test definition

3 épico, considerável, grave, pesado, profundo, solene, subst.

hardness test using vickers test|vickers hardness test theory